What are the characteristics of the production process of vulcanized bar transfer labels?

- 2025-04-29

- China Rubber Hose Vulcanization Label Manufacturer

- 2084

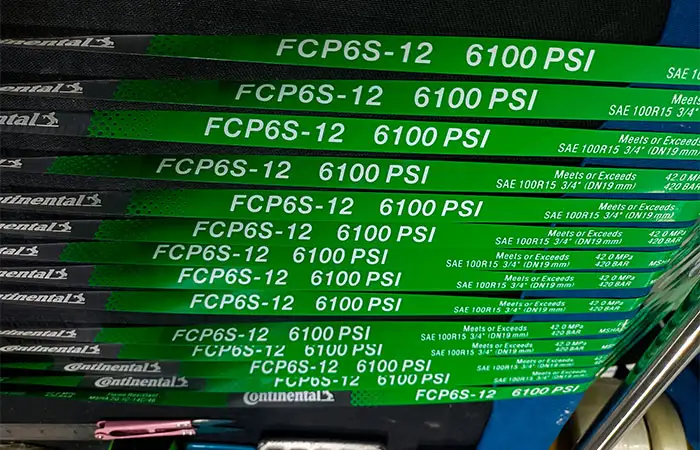

The production process of vulcanized bar transfer labels is based on usage requirements, such as high temperature resistance, friction resistance, good adhesion and long-lasting and clear marking effect. The following introduces the characteristics of the production process of vulcanized bar transfer labels:

1. In order to ensure that the vulcanized bar transfer label maintains stable performance under different environments, films with good thermal conductivity, chemical stability and mechanical strength should be selected. Common ones include polyester (PET), polyimide (PI), etc.

2. The vulcanized bar transfer label is to apply one or more special coatings on the film to improve its adhesion, wear resistance or provide other functions.

3. Choose different printing methods according to different needs. The printing methods of vulcanized bar transfer labels include screen printing, gravure printing, flexographic printing, etc. These printing methods can ensure that high-precision and high-quality text and pattern printing can be achieved even on complex surfaces.

4. The printed vulcanized strip transfer label should be cut according to the requirements to ensure that the final product can fit intact on the surface of the hose.

5. During the entire production process, strict quality monitoring should be carried out for raw materials and intermediate products, and the final finished products should be subjected to temperature resistance and adhesion testing to ensure that each batch of products meets the usage requirements.