-

What are the advantages of customized rubber tube vulcanization labels?2025-11-18What are the advantages of customized rubber tube vulcanization labels? We are a professional manufacturer of customized rubber tube vulcanization labels in China. We are specially designed for different industry scenarios to improve production efficiency and traceability accuracy for enterprises. The rubber tube vulcanization label can be added according to the needs of the enterprise, including the enterprise LOGO, exclusive coding, vulcanization process...

What are the advantages of customized rubber tube vulcanization labels?2025-11-18What are the advantages of customized rubber tube vulcanization labels? We are a professional manufacturer of customized rubber tube vulcanization labels in China. We are specially designed for different industry scenarios to improve production efficiency and traceability accuracy for enterprises. The rubber tube vulcanization label can be added according to the needs of the enterprise, including the enterprise LOGO, exclusive coding, vulcanization process... -

What work should be done before printing hydraulic hose labels?2025-06-11Before printing the hydraulic hose label, it should vary according to the material, process requirements and production quantity of the label. So what should be done before printing the hydraulic hose label? It is necessary to clarify the purpose, size specifications and label content requirements of the hose label, and use professional design software to generate vector files, so as to ensure the printed graphics...

What work should be done before printing hydraulic hose labels?2025-06-11Before printing the hydraulic hose label, it should vary according to the material, process requirements and production quantity of the label. So what should be done before printing the hydraulic hose label? It is necessary to clarify the purpose, size specifications and label content requirements of the hose label, and use professional design software to generate vector files, so as to ensure the printed graphics... -

What should be noted when printing vulcanization labels for rubber hoses?2025-05-07What should be noted when printing curing labels for rubber hoses? This should mainly be controlled from the following aspects: 1. The material of the curing labels must be selected according to the conditions such as the temperature and humidity of the curing process. Since the temperature is high during the curing process, it requires the material of the curing labels to have high flatness and smoothness, which is beneficial for ink adhesion...

What should be noted when printing vulcanization labels for rubber hoses?2025-05-07What should be noted when printing curing labels for rubber hoses? This should mainly be controlled from the following aspects: 1. The material of the curing labels must be selected according to the conditions such as the temperature and humidity of the curing process. Since the temperature is high during the curing process, it requires the material of the curing labels to have high flatness and smoothness, which is beneficial for ink adhesion... -

What are the characteristics of the production process of vulcanized bar transfer labels?2025-04-29The production process of vulcanized bar transfer labels is based on usage requirements, such as high temperature resistance, friction resistance, good adhesion and long-lasting and clear marking effect. The following introduces the characteristics of vulcanized bar transfer label production process: 1. In order to ensure that the vulcanized bar transfer labels maintain stable performance under different environments, you must choose...

What are the characteristics of the production process of vulcanized bar transfer labels?2025-04-29The production process of vulcanized bar transfer labels is based on usage requirements, such as high temperature resistance, friction resistance, good adhesion and long-lasting and clear marking effect. The following introduces the characteristics of vulcanized bar transfer label production process: 1. In order to ensure that the vulcanized bar transfer labels maintain stable performance under different environments, you must choose... -

How to choose rubber hose ribbon manufacturer for beginners: a must-read guide for purchasing managers, bosses and technicians2025-04-28Looking for a high-quality ribbon manufacturer for rubber tube factory? This article provides purchasing managers, bosses and technicians with practical strategies for novices to choose hose ribbon manufacturers, helping you to select reliable suppliers and improve the quality of rubber pipes.

How to choose rubber hose ribbon manufacturer for beginners: a must-read guide for purchasing managers, bosses and technicians2025-04-28Looking for a high-quality ribbon manufacturer for rubber tube factory? This article provides purchasing managers, bosses and technicians with practical strategies for novices to choose hose ribbon manufacturers, helping you to select reliable suppliers and improve the quality of rubber pipes. -

Hose Vulcanization Label Buyer's Guide: 3 Steps to the best Rubber Label2025-04-24Hose vulcanization labels are important for identifying hose information and ensuring safe production. Consider factors such as durability, accuracy, and cost-effectiveness when selecting the right labels.

Hose Vulcanization Label Buyer's Guide: 3 Steps to the best Rubber Label2025-04-24Hose vulcanization labels are important for identifying hose information and ensuring safe production. Consider factors such as durability, accuracy, and cost-effectiveness when selecting the right labels. -

what is a rubber transfer label?2025-03-17rubber transfer labels, sometimes called thermal transfer labels or thermal transfer labels, are a special type of label technology that is mainly used to provide long-lasting, durable markings on various surfaces.

what is a rubber transfer label?2025-03-17rubber transfer labels, sometimes called thermal transfer labels or thermal transfer labels, are a special type of label technology that is mainly used to provide long-lasting, durable markings on various surfaces. -

How to ensure that the rubber hose label is color-coded correctly?2025-03-07ensuring that the rubber hose label is correctly color-coded is essential for safe use and distinction between different types of hoses. here are some steps and suggestions to help you ensure the accuracy of color coding: 1. first determine and follow international or national standards that apply to your product. for example, iso 554 (rubber and plastic hoses and soft...

How to ensure that the rubber hose label is color-coded correctly?2025-03-07ensuring that the rubber hose label is correctly color-coded is essential for safe use and distinction between different types of hoses. here are some steps and suggestions to help you ensure the accuracy of color coding: 1. first determine and follow international or national standards that apply to your product. for example, iso 554 (rubber and plastic hoses and soft... -

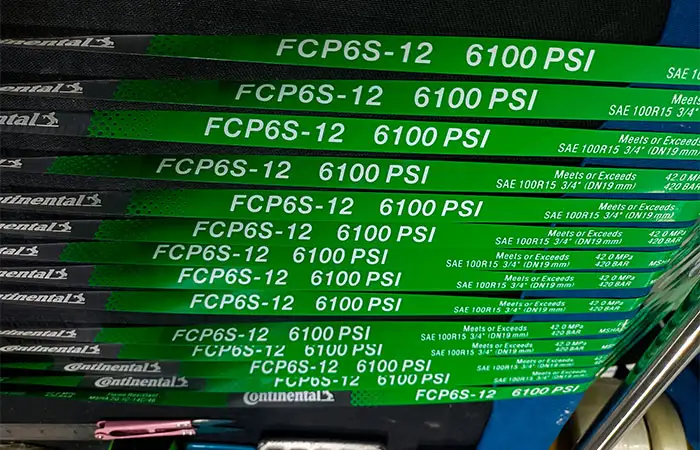

key points for making rubber hose labels2025-02-10when making rubber hose labels, the following key points need to be considered to ensure that the label can provide accurate information and meet relevant standards and regulations: 1. clear identification: the type, size, and working pressure of the hose should be clearly marked on the label. , test pressure and other basic information. this helps users quickly identify soft...

key points for making rubber hose labels2025-02-10when making rubber hose labels, the following key points need to be considered to ensure that the label can provide accurate information and meet relevant standards and regulations: 1. clear identification: the type, size, and working pressure of the hose should be clearly marked on the label. , test pressure and other basic information. this helps users quickly identify soft... -

what conditions must rubber hose labeling materials meet?2025-01-20since the vulcanization process of rubber hose labels involves high temperature and high pressure environments, ordinary label materials may not be able to withstand such conditions. therefore, it is crucial to choose label materials suitable for the vulcanization process: 1. high temperature resistance: able to withstand high temperatures during the vulcanization process without deformation or damage. 2. resistance to chemical corrosion: resistant to vulcanization...

what conditions must rubber hose labeling materials meet?2025-01-20since the vulcanization process of rubber hose labels involves high temperature and high pressure environments, ordinary label materials may not be able to withstand such conditions. therefore, it is crucial to choose label materials suitable for the vulcanization process: 1. high temperature resistance: able to withstand high temperatures during the vulcanization process without deformation or damage. 2. resistance to chemical corrosion: resistant to vulcanization...